Gear Ratios Explained: Unlocking Torque and Crawl Mastery

Why Gear Ratios Are the Heartbeat of Torque and Crawl Control

If you’ve ever wondered why some rigs power up steep boulder fields like mountain goats while others stall or spin, it almost always comes down to gear ratios. This seemingly simple concept is at the very core of torque delivery, crawl control, and drivetrain behavior. Yet it’s often misunderstood, oversimplified, or—worse—completely overlooked in off-road builds.

In this article, we’ll break down understanding gear ratios, focusing on how they shape torque and crawl performance in 4x4 systems. Whether you’re gearing up a trail crawler or tweaking ratios after a tire size upgrade, this guide will walk you through the gritty details—with no fluff, just real, usable insight.

Let’s dig in—because power without control is just wheelspin.

Table of Contents

- What Are Gear Ratios, Really?

- Why Gear Ratios Matter for Torque and Crawl

- Understanding Crawl Ratio in 4WD Systems

- Final Drive vs Transmission Gears vs Transfer Case

- Tire Size and Gear Ratio Mismatch

- High vs Low Gear Ratios: The Constant Tug-of-War

- Common Gear Ratio Mistakes in Off-Road Builds

- How to Calculate the Ideal Gear Ratio

- Gear Swaps: When, Why, and What to Watch For

- Results from Proper Gear Optimization

- FAQs

- Conclusion: Mastering Torque and Crawl Through Precision Gearing

What Are Gear Ratios, Really?

Gear ratios are the mathematical expression of how many times a drive gear must rotate to turn the driven gear once. But let's not let the math speak louder than the meaning.

At its core, a gear ratio is about leverage. Think of it like using a crowbar. A higher ratio gives you more twisting force (torque), just like a longer bar helps pry open a stuck lid. Lower ratios, by contrast, trade off that force for speed—like a shorter lever moving quicker but delivering less push.

In drivetrain terms, it’s the difference between torque multiplication for rock crawling and high-speed efficiency on open terrain. You’re always balancing power delivery against speed. You can’t have it all—but you can choose wisely for your goal.

Why Gear Ratios Matter for Torque and Crawl

Now let’s get to the heart of it: torque and crawl ratio. These two define how a 4WD behaves when the terrain pushes back hard.

Torque isn’t just about engine output. It’s about how that force is transmitted and multiplied through the drivetrain. Gear ratios act as torque amplifiers. Want to inch forward on a ledge at 600 RPM without stalling? That’s a function of proper crawl gearing.

Here’s where things get exciting—and frankly, a little intense. If your gear ratios are too tall (numerically low), you’ll burn your clutch or overheat your torque converter. Too short (numerically high)? You’ll scream the engine with no highway top-end. That’s why understanding gear ratios is the key—not a side note—in your crawl and torque strategy.

Understanding Crawl Ratio in 4WD Systems

Your crawl ratio is the product of:

- First gear ratio (in the transmission)

- Low-range ratio (in the transfer case)

- Final drive ratio (in the differential)

Multiply those three, and you get the crawl ratio—a precise measure of how slowly and powerfully the vehicle can move at idle. Think of it like this: if each turn of the engine moves your wheels barely a few inches, you’ve got mechanical finesse on your side.

For example, let’s say you’ve got:

- A 4.0:1 first gear

- A 2.72:1 transfer case low range

- A 4.56:1 axle gear

Your crawl ratio would be:

4.0 × 2.72 × 4.56 = 49.6:1

That’s decent. But extreme rock crawlers often aim for 80:1 or more. Why? Because torque control at low speed isn't just helpful—it's survival.

Final Drive vs Transmission Gears vs Transfer Case

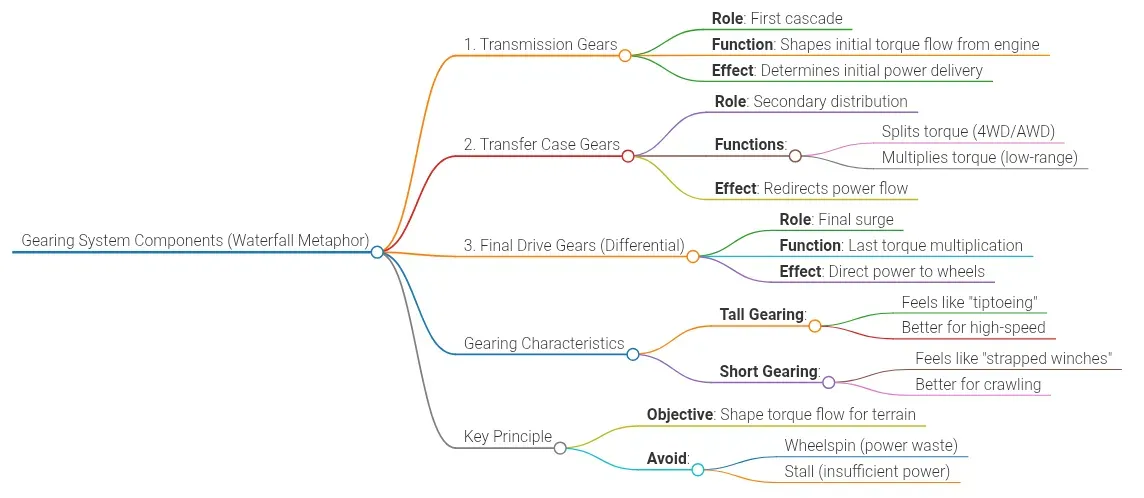

Let’s break these components down with a metaphor: imagine gearing as a multi-stage waterfall.

- Transmission gears are the first cascade—shaping initial flow from the engine.

- Transfer case gears direct that energy further—splitting or multiplying it.

- Final drive gears in the differential are the last, powerful surge before torque hits the ground.

Each stage in this flow shapes how torque feels under your tires. Tall gearing makes it feel like you're tiptoeing across gravel. Short gearing? Feels like you’ve strapped a winch to each wheel.

You want to shape that flow for your terrain—not let it spill uselessly into wheelspin or bog down into a stall.

Tire Size and Gear Ratio Mismatch

Here's a mistake too many builders make: changing tire size without re-gearing.

When you add taller tires—say, from 31s to 35s—you effectively raise your gear ratio. That reduces torque at the wheels, increases strain on the clutch or transmission, and ruins your crawl performance.

Symptoms? The engine bogs on inclines. First gear feels like second. Your crawl control evaporates.

So what’s the fix? Re-gear your axles to match the new rolling circumference. That restores your torque curve, maintains shift quality, and gives you back that confident low-speed control.

High vs Low Gear Ratios: The Constant Tug-of-War

Let’s stir the pot with an old rivalry: high gear ratios vs low gear ratios. Enthusiasts are split.

High ratios (numerically low) like 3.73:1 are great for fuel economy and daily driving. But when you take that same rig off-road, it might stall on a loose incline or lose control descending steep terrain.

Low ratios (numerically high), say 5.13:1 or even 5.86:1, give you crawl power and hill descent control. But now your highway RPMs are screaming and your fuel gauge dips like a cliff edge.

So what's the answer?

Compromise smart. If you’re 70% trail, 30% street, go low. If it’s a daily driver with weekend ambitions, aim middle-ground—but lean toward torque if you're serious about off-road performance.

| Comparison | High Gear Ratios (e.g., 3.73:1) |

Low Gear Ratios (e.g., 5.13:1, 5.86:1) |

|---|---|---|

| Pros | Better fuel economy Smoother highway |

Superior crawl power Hill control |

| Cons | Struggles off-road (stalling, etc.) |

High RPMs on highway Poor fuel economy |

| Best For | Daily driving Fuel efficiency |

Serious off-roading Steep terrain |

| Compromise | 70% street? Mid-range, lean torque |

70% trail? Go low for off-road performance |

Common Gear Ratio Mistakes in Off-Road Builds

Let’s lay them out plainly. Here are the most common gear ratio missteps:

- Skipping the math. People guess instead of calculating crawl ratios.

- Not compensating for tire upgrades.

- Over-gearing for crawl and ending up with unusable highway manners.

- Using mismatched front and rear ratios. This will destroy your transfer case.

- Assuming stock axles can handle deep gears without strength mods.

Gearing is physics. Guesswork breaks things. Precision builds power.

How to Calculate the Ideal Gear Ratio

So how do you pick your ideal gear ratio? Here's a simplified formula used by many 4x4 builders:

New Ratio = (New Tire Diameter ÷ Old Tire Diameter) × Old Ratio

This maintains your engine RPM range for both crawl and cruising. But don’t stop there.

Also consider:

- Transmission ratios

- Transfer case gearing

- Desired RPM at 65–70 MPH

- Engine’s torque band

- Terrain type

Do the math, then sanity-check it against real-world outcomes. It’s never just one number—it’s the whole system.

Gear Swaps: When, Why, and What to Watch For

Gear swaps are more than a bolt-on mod. They're a system-level recalibration. Here's what you need to keep in mind:

- Know your axle housing limits. Not all axles can take 5.38 gears without additional support.

- Upgrade your carriers. Going past a certain point often requires a new differential carrier or locker.

- Adjust your speedometer and shift points. Deep gearing can throw off automatic transmissions and electronic speedometers.

It's not just about installing new gears—it's about optimizing the system.

Results from Proper Gear Optimization

What does correct gear ratio tuning feel like?

- Your engine stays in the sweet spot of its torque band.

- Crawl mode gives you near-idle rock control.

- You no longer smell clutch. Or hear gear whine.

- Your highway RPM drops back into normal range.

- And best of all? Confidence. You feel the drivetrain working with you, not against.

That’s not just performance—it’s peace of mind.

Frequently Asked Questions

What is the best crawl ratio for rock crawling?

A crawl ratio of 60:1 or higher is recommended for technical rock crawling. Some rigs push past 100:1 for extreme terrain.

Can I upgrade to 35" tires without re-gearing?

You can, but you’ll lose torque, slow down acceleration, and hurt crawl control. Re-gearing is strongly advised.

How does the transfer case affect gear ratios?

The low-range in your transfer case multiplies torque. A deeper low-range (e.g., 4:1) massively improves crawl ratio.

Is it bad to have mismatched front and rear axle ratios?

Yes. It causes drivetrain binding, transfer case damage, and unsafe handling. Always match front and rear ratios.

Do automatic transmissions affect gear ratio choice?

Yes. Automatics can absorb torque loss better, but still benefit from correct final drive ratios for low-speed control.

Conclusion: Mastering Torque and Crawl Through Precision Gearing

If torque is the heartbeat of a 4WD drivetrain, gear ratios are the rhythm that gives it purpose. They don’t just move you—they define how you move, where you can go, and how your rig behaves when the ground fights back.

Whether you're clawing through granite ledges or balancing daily drivability with weekend thrill, understanding gear ratios is your key to control, power, and confidence. Crawl smarter. Torque stronger. And above all—gear with intention.

Because in the end, it’s not about having more torque. It’s about having the right torque, at the right time, in the right place. And nothing delivers that like a well-chosen gear ratio.

Comments

Post a Comment