Steering Box Braces and Frame Flex: Do They Really Solve the Problem?

Introduction: When Steering Feels Like a Tug-of-War

You’re hammering through a rocky washout, tires clawing, engine growling. Then you notice it—your steering wheel feels like it’s got a mind of its own. Not just a wiggle, but a vague, unsettling drift. It's as if the truck's front end is trying to shrug off your input. That’s where the conversation begins around steering box braces and frame flex—a debate that’s raged in garages and forums for years. But here’s the big question: Do steering box braces actually prevent frame flex, or are they just a band-aid on a bigger structural issue?

This article isn’t about shallow speculation. We’re going to tear into this topic the same way a wrench hits a stubborn bolt—firm, deliberate, and with every angle considered. From the metallurgy of frame rails to the geometry of steering input load paths, we’ll examine how these components really interact.

Table of Contents

- Understanding Frame Flex in Off-Road Vehicles

- What Is a Steering Box Brace and How Does It Function?

- Steering Load Dynamics: Why It All Starts with Torque

- Common Signs of Frame Flex Around the Steering Box

- How Frame Flex Affects Steering Accuracy and Safety

- The Real Engineering Behind Steering Box Braces

- Misconceptions About What Braces Can and Cannot Fix

- Welding, Bracketing, or Bracing—Which Fix Works Best?

- Compatibility Issues with Aftermarket Suspension or Bumpers

- Why Steering Box Braces Sometimes Fail

- Steel Types, Bolt Tension, and Brace Geometry Explained

- How Steering Box Braces Interact with Factory Welded Crossmembers

- Frame Repair vs. Reinforcement: When Braces Are Too Late

- Maintenance Tips to Maximize Brace Performance

- Common Installation Mistakes and How to Avoid Them

- Do You Need One? A Practical Buyer’s Checklist

- FAQs: Steering Box Braces and Frame Flex

- Conclusion: The Right Fix for the Right Problem

Understanding Frame Flex in Off-Road Vehicles

Frame flex isn’t just a dramatic term tossed around by suspension junkies. It’s real, measurable, and progressive. In vehicles with traditional body-on-frame construction, especially 4WD trucks with solid front axles, steering box-induced frame flex occurs when lateral torque from the steering linkage twists the frame rail it's bolted to.

Imagine holding a pool noodle at one end while someone tugs and twists the other—it resists, but it deforms. That’s your frame during steering inputs on uneven terrain.

And while that flex might seem minor at first, over time, it causes cumulative distortion:

- Misalignment between pitman arm and drag link

- Excess play in steering feel

- Premature wear in tie rod ends and sector shafts

- Stress fractures radiating from the steering box mounts

What Is a Steering Box Brace and How Does It Function?

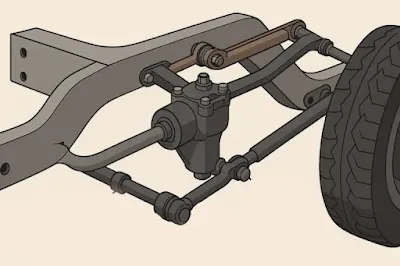

A steering box brace is a horizontal stabilizer that mounts between the steering box and a rigid portion of the vehicle’s crossmember or opposite frame rail. Its purpose is to triangulate the load path—absorbing and redistributing torque that would otherwise twist the driver-side frame rail.

It’s like bracing a ladder between two trees instead of letting it lean against one—you reduce sway, distribute weight, and enhance stability.

But the devil's in the design. A well-engineered brace:

- Aligns perfectly with sector shaft output

- Includes bearing support to reduce vertical shaft load

- Connects across a rigid structure without introducing new flex points

When it works, the steering system feels tighter, more direct, and less prone to mid-turn hesitation or vague input response.

Steering Load Dynamics: Why It All Starts with Torque

Steering isn't just directional—it’s dynamic torque transfer. The steering box converts rotational force from your steering wheel into linear force via the pitman arm, sending that energy through the drag link, which then moves the steering knuckles.

During this transfer, the steering box generates reaction torque. That torque pushes back against the frame. And if the frame flexes, you lose some of that motion in deformation instead of wheel movement.

Here’s a quick analogy: Try turning a screwdriver while the handle bends. Some of your energy is wasted. That’s what happens when frame flex eats your steering torque.

Now, magnify that stress by crawling through rock gardens with 37-inch tires aired down. The steering box is under siege—and the frame's left to absorb the abuse.

Common Signs of Frame Flex Around the Steering Box

Not sure if your ride is suffering from frame flex? Here are the red flags:

- Cracks around steering box bolt holes

- Uneven bolt torque or frequent loosening

- Noticeable side-to-side frame movement when steering parked

- Sector shaft rubbing or grinding against brace bushings

- Looseness in steering despite tight linkage components

And worst of all—a wandering front end that feels like it’s resisting your commands. It’s unnerving, especially under load.

How Frame Flex Affects Steering Accuracy and Safety

Steering should be crisp and confident. When frame flex distorts steering geometry, inputs become delayed and inconsistent. That’s not just frustrating—it’s dangerous.

The sector shaft, pitman arm, and drag link alignment depends on fixed angles. If the frame distorts, those angles change in real time. That’s when you get:

- Bump steer

- Off-axis pitman motion

- Degraded turning radius under load

In off-road conditions, this can mean the difference between crawling a ledge or sliding off it. On-road, it compromises lane-holding during high-speed maneuvers or emergency corrections.

The Real Engineering Behind Steering Box Braces

So, do steering box braces stop frame flex? Well, they resist it, but only if the load path is properly reinforced.

Many braces use a clamshell or bearing-supported design that captures the sector shaft tip. This reduces vertical and lateral shaft deflection. The brace then spans to a solid crossmember or opposite frame rail, creating a two-point load bridge.

But not all designs are equal. Braces that bolt to thin metal or rely solely on the original frame’s rigidity merely shift stress—they don’t neutralize it.

Critical engineering elements:

- Thick-gauge steel construction with minimal torsional give

- Full-width attachment with grade 8 or 10.9 bolts

- Preloaded design to eliminate play under load

- Accurate sector shaft bearing centering

When done right, steering becomes immediate. Not artificially tight—just appropriately responsive.

Misconceptions About What Braces Can and Cannot Fix

Let’s bust a myth. A steering box brace won’t fix an already cracked or fatigued frame. It’s not a magic wand. Think of it more like a weight belt for your steering system—it supports under pressure, but won’t heal injuries.

Some assume adding a brace will also eliminate death wobble. But here’s the thing: death wobble is usually caused by alignment and suspension harmonics, not frame flex. The brace might reduce a variable, but it’s not a cure-all.

Also, some believe all braces are the same. Far from it. Geometry, weld quality, bracket fitment, and bushing tolerances all play into long-term success.

Welding, Bracketing, or Bracing—Which Fix Works Best?

When frame flex has already caused damage, you’re left with options:

- Weld-in reinforcement plates

- Bolt-on crossmember braces

- Steering box braces with sector shaft support

Each has a place. Welding adds rigidity but is invasive and irreversible. Brackets can tie the frame together, but without sector shaft stabilization, they fall short. Braces offer a middle ground—non-permanent but structurally significant.

Your choice depends on condition. If the frame’s already fatigued, you’ll likely need both welding and bracing. If it's still sound but showing minor deflection, a brace alone might be your best bet.

Compatibility Issues with Aftermarket Suspension or Bumpers

This is where things get tricky. Some aftermarket bumpers, winches, or high-clearance suspension components interfere with brace mounting locations.

Common clashes include:

- Tie rod relocation kits

- Hydraulic assist rams

- Winch trays that block the front crossmember

Always test-fit. And don’t assume two products will play nice just because they’re both labeled “HD” or “off-road.” Sometimes you have to get creative with shims, custom brackets, or even a plasma cutter.

Why Steering Box Braces Sometimes Fail

Yes, they can fail. Sometimes spectacularly.

Reasons include:

- Incorrect torque spec during install

- Inferior steel bending under load

- Poor welds or cracked bushings

- Brace not preloaded—leaving play that grows into damage

And let’s not forget—the brace relies on what it mounts to. If the crossmember or opposite rail isn’t up to the task, the brace may just amplify flex elsewhere.

Steel Types, Bolt Tension, and Brace Geometry Explained

Precision matters. Not all steel is created equal. Look for braces made from:

- A36 or 1018 mild steel for ductility

- DOM tubing for high-load sectors

- Laser-cut gussets with reinforced weld zones

Bolt tension is crucial. Under-torque leads to slop. Over-torque can crush bushings or distort mounts. Always use a torque wrench and thread locker.

Brace geometry should mimic load flow—not fight it. The best designs tie into both horizontal and vertical force planes, resisting not just twisting but lift and drop.

Frame Repair vs. Reinforcement: When Braces Are Too Late

When the cracks spider across the steering box mount or welds start separating, a brace is no longer the front-line fix. Now you need reinforcement plates or full-boxed frame sections.

That said, even after repairs, adding a steering box brace ensures you don’t land in the same pit twice. Consider it insurance after surgery.

Maintenance Tips to Maximize Brace Performance

- Check bolt torque every 10,000 km or after hard trail use

- Inspect bushings for wear or cracking

- Reapply thread locker if bolts are ever removed

- Watch for sector shaft side wear—especially after impacts

A little vigilance goes a long way.

Common Installation Mistakes and How to Avoid Them

- Installing without aligning the sector shaft perfectly

- Skipping anti-seize on steel-to-steel interfaces

- Failing to preload the brace before tightening bolts

- Not checking for clearance with steering linkage in full sweep

Double-check. Then check again with the wheels fully turned.

Do You Need One? A Practical Buyer’s Checklist

You should seriously consider a steering box brace if:

- You run oversized tires or beadlocks

- You off-road frequently on rocks or steep terrain

- You feel steering vagueness or witness frame deflection

- Your rig has over 150,000 km and shows mount fatigue

- You’ve already replaced your steering box more than once

Still unsure? Try having someone turn the wheel with the engine off while you watch the steering box from below. If it’s dancing, it’s time.

FAQs: Steering Box Braces and Frame Flex

Q: Can a steering box brace fix loose steering?

A: It can help, but only if the looseness comes from frame flex—not worn tie rods or box internals.

Q: Will a brace fit with my winch bumper?

A: Maybe. Some designs interfere. Always check clearances first.

Q: Do I need welding experience to install one?

A: Most bolt-on kits require no welding, but frame damage may call for it.

Q: Is a bearing-supported brace better than a basic cross brace?

A: Usually yes, especially under hard use. It stabilizes the sector shaft directly.

Conclusion: The Right Fix for the Right Problem

Let’s bring it back full circle. Steering box braces don’t eliminate frame flex outright—but they’re one of the smartest reinforcements you can bolt on. When engineered and installed correctly, they transform steering from floaty to firm, from unsure to surgical.

But they aren’t a cure-all. They’re a tool in the arsenal. Frame integrity, suspension geometry, and steering alignment all matter too.

So, do they work? Absolutely. Just not in isolation or with blind faith. Know your frame. Know your brace. And most of all—know what problem you’re trying to solve.

Your steering system shouldn’t feel like it’s guessing. With the right brace, it doesn’t have to.

Comments

Post a Comment