Electric vs Manual Transfer Case Shifters: Full Comparison for Off-Road Control

Introduction

When you’re deep in the backcountry with your rig crawling over slickrock or clawing through soaked clay, the last thing you want to question is your transfer case shifter. Whether it’s a sleek switch on the dash or a solid lever between the seats, this one component decides if torque goes to two wheels or all four. And the debate? It’s alive and well: electric vs manual transfer case shifters.

Which one’s better? Well, it depends. And no, that’s not a cop-out—it’s a fact shaped by how you drive, where you drive, and how you want your rig to feel under pressure. This guide dives hard into the mechanical guts and nuanced realities of both systems—because this isn’t just about switching modes. It’s about predictability, control, and resilience when things get ugly.

Table of Contents

- What is a Transfer Case Shifter?

- How Manual Transfer Case Shifters Work

- How Electric Transfer Case Shifters Work

- Comparing Electric vs Manual Transfer Case Shifters in Off-Road Use

- Reliability and Failure Modes

- Control, Feedback, and Driver Engagement

- Maintenance and Troubleshooting

- Common Mistakes and Misconceptions

- Which Shifter Is Best for You?

- Frequently Asked Questions

- Final Thoughts and Practical Recommendation

1. What is a Transfer Case Shifter?

Let’s start with the basics: a transfer case shifter is the mechanism that allows the driver to engage different drive modes in a 4WD system—2H (two-wheel drive high), 4H (four-wheel drive high), and 4L (four-wheel drive low). It controls how torque is distributed from the transmission to the front and rear axles.

Think of it like a command center for your drivetrain. Pulling a lever or pressing a button may seem small, but it sends a signal—mechanical or electronic—that physically moves components inside your transfer case to reconfigure power delivery.

2. How Manual Transfer Case Shifters Work

A manual transfer case shifter is typically a floor-mounted lever that connects directly (or semi-directly through linkage) to the transfer case itself. When you move the shifter, you’re physically engaging gears inside the case.

It’s mechanical. Tactile. Honest.

When you yank that lever into 4L, you’re feeling the engagement of a low-range gearset designed to multiply torque. You’re moving a shift fork, compressing detents, and possibly aligning synchros or sliding collars. It’s a straight-up mechanical handshake between driver and drivetrain.

Advantages?

- No electronics to fail. No relays, sensors, or motors that get confused or lazy.

- Instant feedback—if it grinds, sticks, or pops, your hands and ears will know.

- Works under power (with finesse)—many skilled drivers can match speeds and engage without a complete stop.

But here’s the rub—manual shifters can be clunky, and some require quite a bit of throw. In frigid conditions or after hours of deep mud, the lever might stiffen up or even jam. Linkage bushings wear. Misalignment happens. It’s not flawless—but it’s usually fixable with tools and grit.

3. How Electric Transfer Case Shifters Work

In contrast, an electric transfer case shifter uses switches or buttons that trigger electric actuators or servo motors to move components inside the transfer case. You’re not directly manipulating gears—you’re asking a control module to do it for you.

The system involves:

- A dash-mounted switch

- A transfer case control module (TCCM)

- Electric shift motor

- Position sensors

- Often, integration with ABS, traction control, and CAN bus

It’s smoother. Quieter. And it automatically handles synchronizing, so you don’t need to worry about gear speed matching. For daily drivers and those who like plug-and-play ease, it’s incredibly convenient.

But there’s a catch—and it’s not small. The system relies on perfect communication between multiple components. If a sensor misreads a signal or a motor hesitates due to resistance (say, caked mud or electrical noise), the whole shift might fail silently.

Worse? It could leave you stuck in 2WD just as you hit a steep climb.

4. Comparing Electric vs Manual Transfer Case Shifters in Off-Road Use

Let’s get real—when you’re off the pavement, the stakes change.

Manual shifters give you control that’s immediate and brutally honest. If the lever won't budge, you know something is binding. You don’t need a dash light to tell you—it tells you through your fingertips. And if your rig is twisted up on uneven terrain, you can often finesse the shift through feel and skill.

Electric shifters add a layer of convenience but remove a layer of feedback. You press a button and hope. If something goes wrong, diagnostics get murky. Maybe it's the TCCM. Maybe it’s the shift motor. Maybe it’s just cold weather messing with a position sensor.

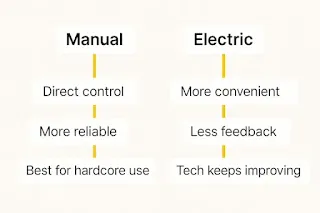

So which is better for off-roaders? That depends:

- Rock crawlers and overlanders often lean manual—reliability and physical feedback are paramount.

- Weekend warriors or trail cruisers may prefer electric—it’s easier, cleaner, and integrates with modern vehicle systems.

But let’s not forget: electric systems are getting smarter. Some now feature automatic transfer case modes, intelligent torque biasing, and even auto return to 2H at high speeds. So the gap is narrowing.

5. Reliability and Failure Modes

Here’s where things get a little tense.

Manual systems tend to fail slowly. Linkages wear. Bushings get sloppy. But they usually give plenty of warning—grinding, resistance, noise.

Electric systems can fail without notice. And the diagnostics? Not always straightforward. You might chase a ghost code through wiring diagrams for days only to find it was a dirty ground or a corroded sensor connector.

Also consider this: moisture is the sworn enemy of electric shifters. If your actuator gets soaked, even the best dielectric grease won’t always save it. One buried water crossing can be enough to short a motor or fry a TCCM.

Manual shifters, by contrast, don’t care about wet socks—they just need mechanical engagement.

6. Control, Feedback, and Driver Engagement

Let’s shift gears into driver psychology.

When you engage a manual transfer case shifter, there’s a primal satisfaction. A clear click. A change in drivetrain tension. You know it’s in. It’s the same feeling as chambering a round or slamming a bolt—mechanical certainty.

Electric shifters? They remove you from the loop. You press a button, wait for a blink, and hope. That’s not necessarily bad—but it changes the driver’s relationship with the drivetrain.

For some, that’s fine. For others, especially those with a passion for feedback and direct control, it can feel alienating.

7. Maintenance and Troubleshooting

Manual shifters are often easier to service. They consist of physical linkage rods, pivot points, and lever arms. If it binds, you can grease it. If it wears, you replace a bushing.

Electric systems, on the other hand, require scanning for codes, checking voltages, inspecting wiring harnesses, and sometimes replacing expensive modules. And if your transfer case motor fails in 2WD on a trail? Good luck finding a fix without a spare actuator or scan tool.

Some rigs are equipped with both manual range selection and electric mode selection—a hybrid system. These can offer the worst of both worlds when not maintained properly. Complexity is always a trade-off.

8. Common Mistakes and Misconceptions

Let’s bust a few myths:

- "Electric shifters are always better because they're newer." Not necessarily. Newer doesn’t mean more reliable, especially under harsh off-road conditions.

- "Manual shifters can’t fail." They can and do—especially from bent linkage or misaligned forks.

- "You can shift into 4L at any speed with electric shifters." Absolutely not. Transfer case internals still follow mechanical rules. Always stop before shifting into 4L.

- "Electric systems auto-fix themselves after a reset." Rarely. Most require a scan tool and full troubleshooting.

9. Which Shifter Is Best for You?

Here’s the question that really matters.

If you prioritize:

- Simplicity

- Off-road reliability

- Tactile feedback

…then a manual transfer case shifter is probably your best bet.

But if you value:

- Ease of use

- System integration with other vehicle electronics

- A clean, modern cabin feel

…then the electric transfer case shifter might serve you better.

Ultimately, it's about confidence—knowing that when traction disappears, your transfer case won't.

10. Frequently Asked Questions

Q: Can I convert an electric transfer case to manual?

A: Sometimes. Some transfer cases allow retrofit kits or gear-based mods, but it's model-dependent and can get costly.

Q: Do electric shifters work in low battery situations?

A: Not always. Low voltage can cause shift motor failure or glitchy behavior.

Q: Are manual shifters more durable?

A: Generally yes, but they’re not immune to abuse or neglect.

Q: Is there a hybrid option?

A: Some vehicles use part-time electric actuation and manual range selection—offering a middle ground.

11. Final Thoughts and Practical Recommendation

So—manual vs electric transfer case shifters. This isn’t a clean-cut win for either side. Like choosing between an analog watch and a smartwatch, it depends on what you trust under pressure.

Manual systems offer pure mechanical reliability, but at the cost of comfort and finesse. Electric systems provide ease and automation, but require you to trust invisible circuits over cold metal certainty.

If your build is aimed at high-stakes terrain—go manual. If it’s a refined machine that sees more commute than canyon, go electric. Either way, know your system. Understand its signals, quirks, and limits. That way, the next time you reach for low range, you’ll do it with certainty.

And that’s worth everything when the trail gets real.

Comments

Post a Comment